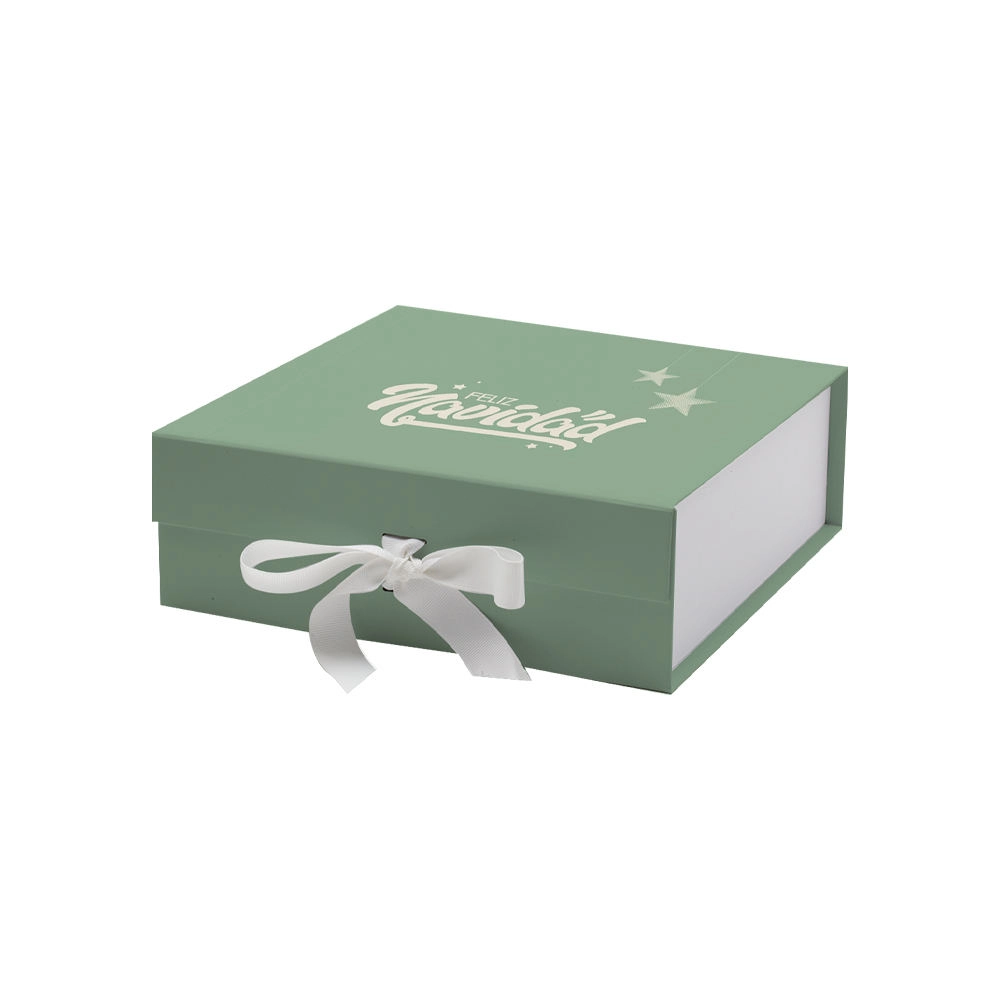

맞춤형 자석 잠금 선물 상자

Printing Handling: Matt Lamination, Varnishing, Stamping, Embossing, Glossy Lamination, UV Coating, VANISHING, Gold Foil, Custom Design

Design: Customer's specific requirements

Surface Finishing: Matt/Glossy lamination, Stamping, Spot UV, Debossing, Embossing, etc.

Shape: Customized Different Shape

Material Option: 1-4mm Greyboard+art Paper /Special Paper

Sample Time: about 5-7 normal days

MOQ: 500

선물 문화가 팽배한 현대 사회에서, 잘 포장된 선물은 단순히 선물 그 자체를 넘어, 주는 사람의 진심과 진심을 담아 전달합니다. 선물의 "첫인상"을 좌우하는 만큼 포장의 중요성은 자명합니다. 자석 선물 상자는 혁신적인 개폐 방식으로 기존 포장의 한계를 뛰어넘어 선물에 특별한 매력을 더합니다. 단순한 선물 용기가 아닌, 예술성과 기능성이 완벽하게 조화를 이루는 제품입니다. 이제, 맞춤형 자석 선물 상자의 놀라운 세계를 탐험하고 다양한 선물에 어떻게 새로운 가치를 더할 수 있는지 살펴보겠습니다.

— 맞춤형 자석 선물 상자의 장점

편리한 개폐 경험:

자석 디자인은 기존의 버클 방식을 대체합니다. 살짝 다가가기만 하면 뚜껑과 상자 본체가 정확하게 흡착되어 닫힙니다. 열 때는 약간의 힘만 주면 됩니다. 조작이 간편하고 매끄러워 사용자의 선물 상자 개봉 편의성을 크게 향상시키고, 받는 사람에게는 편안하고 즐거운 개봉 경험을 선사합니다.

포장의 질감을 개선하세요:

자석 흡착 기술을 활용하여 선물 상자에 섬세하고 고급스러운 분위기를 더했습니다. 일반 포장재와 비교했을 때, 자석 선물 상자는 닫았을 때 더욱 단단하게 고정되며, 뚜껑과 상자 본체의 연결 부위가 자연스럽고 매끄러워 눈에 띄는 틈이 없습니다. 전체적인 외관이 더욱 섬세하고 고풍스러워 선물의 품격과 가치를 크게 높여줍니다.

제품 보호 강화:

운송이나 보관 중에도 견고한 자석 잠금 장치는 선물 상자가 실수로 열리는 것을 효과적으로 방지하여 상자 안의 물품을 안정적이고 안전하게 보호합니다. 특히 깨지기 쉬운 선물의 경우, 자석 상자는 흔들림이나 충돌로 인한 물품 손상 위험을 줄여 선물이 받는 사람에게 손상 없이 전달되도록 보장합니다.

독특한 외관:

Customized magnetic gift boxes are extremely flexible in appearance design. They can break through the limitations of traditional square and rectangular shapes and be designed into unique shapes such as round and irregular shapes. The magnetic function is cleverly integrated into various shapes, which not only does not affect the appearance but also provides more possibilities for the realization of unique shapes, making the gift box stand out from many packages and attract consumers' attention.

— Customization Points of Magnetic Closure Gift Box

Size adaptation

Accurately measure the length, width, height, and shape of the gift, consider the direction and space reserved when placing the gift, and ensure that the internal size of the gift box fits the gift tightly without squeezing it. At the same time, the rationality of the external size in transportation, display, and other scenarios should be taken into account to avoid inconvenience caused by being too large or too small. For example, to customize a gift box for an irregularly shaped crystal ornament, it is necessary to measure the dimensions of the protruding and recessed parts of the ornament in all directions, and design a box size that can perfectly wrap the ornament without wasting too much space.

Material selection

Common ones include grayboard paper, whiteboard paper, cardboard, etc. Gray board paper is affordable and has good stiffness. It is suitable for products with strict cost control and relatively low requirements for appearance; whiteboard paper has a smooth surface, high whiteness, and excellent printing effect. It is often used for gift packaging with high requirements for appearance display; cardboard has strong toughness and high folding resistance, can withstand a certain amount of pressure, and is suitable as the main structural material of gift boxes.

Magnetic selection

Magnetic strength:

Choose a magnet with appropriate magnetic strength according to the size, weight, and preciousness of the gift box. Small and light gift boxes can choose magnets with weaker magnetic strength, which can meet the closing requirements and are easy to open; large, heavy, or gift boxes containing valuables need to be equipped with magnets with strong magnetic strength to ensure that the lid is firmly closed during transportation.

Magnet type

Common ones include neodymium iron boron magnets and ferrite magnets. Neodymium iron boron magnets have strong magnetic properties and small sizes and can achieve good magnetic attraction in a small space, but the price is relatively high; ferrite magnets are more affordable and have moderate magnetic properties. They are suitable for gift box customization that is cost-sensitive and does not require particularly high magnetic properties.

Installation position: Carefully design the installation position of the magnet on the lid and the box body to ensure that the two can be accurately adsorbed and tightly closed. Usually, the magnets are symmetrically installed on the edges of the lid and the box body to ensure uniform force and stable closure.

Printing Technology

Color printing

Adopt advanced printing technology, such as CMYK four-color printing, spot color printing, etc., to accurately restore the colors in the design draft. For brands or designs with special color requirements, spot color printing can mix colors that are completely consistent with the brand color, ensuring the unity and accurate communication of the brand image.

Surface treatment

Through hot stamping, hot silver, UV, embossing, and other surface treatment processes, the gift box is given a unique texture and visual effect. Hot stamping and hot silvering processes can present a metallic luster on the box surface, enhancing the luxury of the gift box; UV technology can form a high-brightness, high-hardness protective layer on the surface of a specific pattern or text, enhancing the visual impact; embossing technology can create a three-dimensional texture effect, such as leather texture, cloth texture, etc., enriching the touch and appearance of the gift box.

Structural Design

Conventional structure optimization

Based on conventional structures such as traditional top and bottom covers and book-shaped boxes, it is optimized in combination with the magnetic suction function. For example, in the top and bottom cover structure, the edges of the box cover and the box body are designed to fit each other in a bevel, and with a magnetic suction device, it is more tightly closed and the appearance is more simple and generous.

Innovative structural design

A unique structure can be designed according to the characteristics of the gift and the usage scenario. For example, a layered magnetic box can be customized for a combination of multiple cosmetics. Each layer is separated by magnetic attraction, which can not only facilitate the classification and storage of cosmetics but also present a rich display effect when opened, improving the user experience.

-

위챗

+8613616008761

위챗

+8613616008761 -

이메일

이메일

-

전화

+86-136-1600-8761

전화

+86-136-1600-8761

ko

ko en

en es

es ru

ru fr

fr de

de it

it ja

ja ar

ar pt

pt ko

ko tr

tr nl

nl fi

fi